Custom Hermetic Seals

RHSeals has created thousands of custom hermetic seal designs for customers in a broad range of industries. We help you achieve greater flexibility in your projects with cost-effective custom solutions and short lead time. If an industry standard seal doesn’t meet your specifications, we’ll work with you to create a new standard!

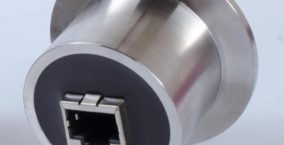

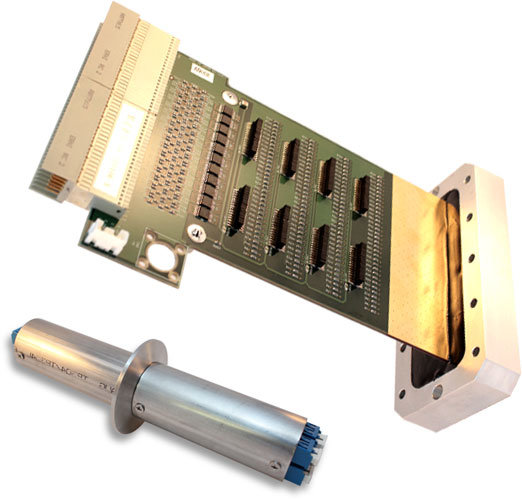

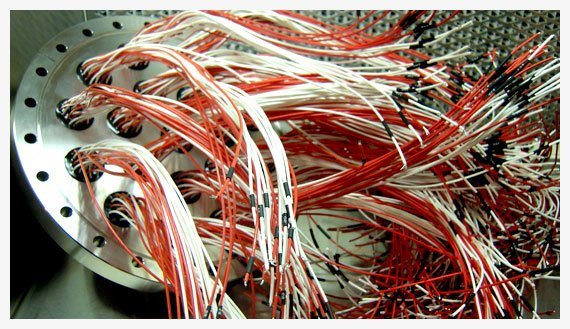

We can build hermetic seals for nearly any connector, cable or wire feedthrough, flex circuit, and thermocouple, including coax, fiber optic, computer equipment connectors, and sealed military connectors. We also make large flanges and portplates with multiple hermetic feedthroughs mounted to the plate, tested and ready for installation. These large conflat flanges often have hundreds of connectors and wires sealed into them.

Our team is dedicated to fully supporting your company from the design stage through the life of your product. Every seal and feedthrough we manufacture receives a rigorous electrical and leak test and visual inspection and comes backed by a limited lifetime warranty. Whether you need a prototype, need to seal an existing wire or cable in your system, or need assistance designing a hermetic seal for your application, contact us for help.

Choosing the Right Hermetic Seal

When you have a system requiring a hermetic feedthrough and seal, it’s important to choose the right materials that will remain robust and effective when the system is in use. Our engineering team specializes in understanding the types of hermetic feedthroughs and seals used in many industries to help you choose the right materials for your application.

Benefits of Epoxy Seals

While epoxy seals have a bad reputation for being “non-hermetic,” the truth is, epoxy seals can perform just as well or even better than ceramic and glass seals in many applications. Our epoxy seals have outgassing and leak rates as low as ceramic seals with even better flexibility in low and high volume needs. Epoxy seals are the best choice for custom shapes and designs. Frequently used in fiber optic and electrical hermetic seals, epoxy seals can effectively seal gases and fluid, including helium gas, with very low helium gas rates.

With excellent resistance to oils and gasoline, epoxy seals are also the ideal choice for energy, aerospace, and automotive industries with the ability to withstand high pressure and temperatures ranging from -100C to 250C.

Epoxy seals are also a common alternative to ceramic-to-metal and glass-to-metal seals in semiconductor manufacturing given today’s shielding requirements and space constraints. In semiconductor manufacturing, the typical benefits of glass-to-metal seals, such as extreme temperature resistance and resistance to corrosive chemicals, are not needed. When maintaining a clean vacuum chamber is the top priority, epoxy seals beat glass-to-metal in terms of versatility and cost.

Epoxy offers the best of both ceramic and glass seals at a lower cost. Epoxy hermetic seals even come with the design flexibility to seal copper alloy pins or wires rather than using the far less electrically conductive nickel-iron pins used in glass hermetic seals. Epoxy seals can be routed through tight spaces and angles, tightly seal any feedthrough shape, and handle any type of cable or wire. They are frequently used to solve design challenges that can’t be addressed easily with glass or ceramic seals.

Our Process

Our experienced engineering team oversees every made-to-order hermetic seal project from the early design stages through the manufacturing process. Most of our custom pressure feedthrough and vacuum feedthrough seals begin with an email from a customer with a specific fiber optic, cable, or wire that is already in their system but needs to be sealed. If you can supply the connector or wire, it can be used to create your custom RHSeals hermetic seal.

We take the time to understand your application to ensure your feedthrough will work as intended.

This means we will ask questions related to:

- Frequency of the system

- Wire length and gauge

- Number of conductors

- Pressure or vacuum level

- Electrical requirements

- Temperature range

- Gases or liquids that will be in contact with the system

Our engineering and sales teams will work together to provide a detailed quote based on your specifications.

If you are ready to move forward, we will create a detailed drawing for your approval before our manufacturing process begins. Our sales and engineering teams will work with you to complete the process as quickly as possible to deliver a robust and cost-effective seal for your application delivered promptly.

Whether you already have drawings for your needed feedthrough, you have a wire or cable in your system that needs to be sealed,or you are interested in manufacturing a prototype, contact us today to receive a detailed quote.

Why RHSeals?

While a custom seal may sound like an expensive solution, our engineering team specializes in flexible tooling to reduce lead time and product costs. Our custom seals prevent the problems associated with standard seals that aren’t quite right, including high maintenance expenses, wasted space, and unnecessary part replacement.

With limitless flexibility in design, a custom hermetic seal from RHSeals may be the best solution for your project.

RHSeals is committed to providing you with the custom fit you are looking for while remaining a cost-effective option. We process low volume, high volume, and prototype orders with the same dedication to on-time shipment.

Even custom seals can ship in just two weeks with full support from our engineering team to create the perfect hermetic seal for your application. We even guarantee made-to-order hermetic seals to be shipped by the promised date with a limited lifetime warranty on every seal we manufacture. Whether you need a prototype or you already have a cable or wire in your system that needs sealed, we can help.

Contact RHSeals to develop a drawing for the hermetic seal you need for your application and receive a detailed quote.

VIEW SOME OF OUR

PRODUCTS

RHSeals can create a hermetic seal for almost any connector you can find.

100% of parts go through a rigorous leak, electrical, & visual inspection.

One stop shop complete wire harnesses, electrically tested with our computer controlled equipment.