WIRE HARNESS OPTIONS

RHSeals offers many options in wire or cable harness manufacturing. Because not every cable harness is required to be hermetic, RHSeals uses its manufacturing expertise, automated equipment, and its large inventory of wires and cables to offer a variety of harness types. With capability to manufacture a custom cut single wire at high volumes to a one off complex wire harness with multiple terminations, RHSeals can meet any challenge.

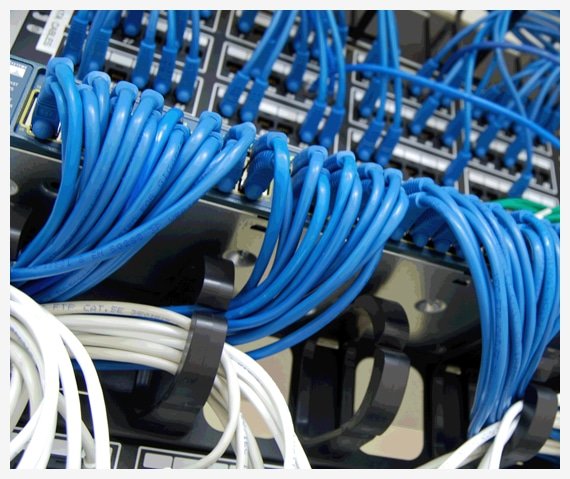

Cable harnesses are used to consolidate the number of wires or cables by bundling them into a group for better resistance to vibration, moisture, and other threats while making installation easier. Having a fully tested terminated harness further increases value added to our customers by allowing direct installation into their systems.

Cable harnesses are frequently used in automobiles and construction machinery to bind cables and wires together to secure them against the effects of moisture, vibration, and abrasion. Harnesses can range in size from small enough for a car stereo system or computer to large cable bundles for spacecraft.

At RHSeals, we design and manufacture custom wire harnesses to fit your exact specifications.

Cable Harnesses

A cable harness is an exterior sheath that covers cables and wires with a thermoset or thermoplastic material. Cable harnesses bundle cables and wires that are already protected by sheaths.

Cable harnesses are basic solutions that serve many purposes:

- Low-cost solution to keep an electrical system organized.

- Speeds installation as cables or wires now have a decreased size and improved maneuverability. Only one harness needs to be installed as opposed to multiple wires or cables.

- Space-saving solution that eliminates multiple openings, cables, and wires and optimizes space when wires are constricted into a bundle.

- Offers better protection against vibration, friction, and moisture.

- Reduces the risk of a short or electrical issues.

- Customization with desired colors and text to reduce maintenance and installation time.

Cable Assemblies

Wire harnesses and cable assemblies are terms that are often used interchangeably but there are differences. A cable assembly is a collection of cables or wires sheathed in a more intensive product such as shrink-wrapped thermoplastic or thermoplastic rubber. A cable assembly serves a similar function as a wire harness to keep cables or wires organized, but it’s suited for different environments.

Cable assemblies are made for specific environmental factors. Assemblies come in a variety of sizes and shapes and are designed to shield cables and wires from moisture, abrasion, friction, heat, compression, and other environmental hazards. A cable assembly is a more robust product for extreme environmental conditions.

Automotive Cable Harnesses

Cable harnesses are a crucial element in all modern vehicles, including assembling brake lights, power door locks, power windows, and central locking.

As the electrical and electronic content in vehicles becomes more complex, the demand for specialized wire harnesses continues to increase.

Automotive manufacturers increasingly rely on custom wire harnesses rather than standard assemblies. Custom assemblies can be used to create lightweight cable harnesses without sacrificing reliability and safety.

Custom Cable Harnesses and Assemblies

Our non-hermetic cable harnesses are designed based on your electrical and geometric specifications. The system wiring diagram is the starting point for designing wire harnesses, as this diagram contains the signal paths and information about necessary wire types and gauges. This diagram is used to determine routing paths and how wires can be routed to determine the harness geometry.

After cables or wires are cut to the correct length, the ends are stripped to expose the core, which is fitted with any necessary terminals or connectors. Cables are then assembled to your design specifications to form the harness.

Providing a quality harness is important to RHSeals. Every harness is electrically tested on computer controlled equipment, and any termination is tested per the manufacturer’s specifications. The electrical tests include tests for high resistance, hi-pot tests, and checks for proper wiring. RHSeals wants to ensure our customers receive high quality harnesses ready for their production line.

Though our automated equipment cuts wires and cables with extreme accuracy, cable harnesses are manufactured by hand, as they require complicated processes such as routing wires through sleeves and crimping terminals into wires.

VIEW SOME OF OUR

PRODUCTS

No products found