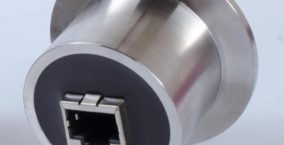

Hermetic Connectors

Hermetic connectors are used to separate high-pressure, corrosive, or high-temperature conditions on one side of an inert vacuum or atmosphere to the other side. These connectors can also be used to maintain a delicate pressure differential between two environments.

RHSeals engineers and manufactures a wide variety of hermetically sealed connectors ranging from sealed USB to large multipin mil-spec connectors.

Our connectors are suitable for use in a broad range of industries such as aerospace, automotive, military, and research and may be customized to the precise specifications of your application. We can create an epoxy hermetic seal around virtually any connector type.

Epoxy Sealed Connectors

The primary purpose of a seal is passing electrically conductive wire through a bulkhead without leakage. For decades, the only way to achieve this was attaching the wire to a pin sealed in ceramic or glass. Epoxy seal technology has eliminated the cost and design constraints of ceramic and glass. By creating an uninterrupted passage, electrical reliability is actually increased and the cost is lowered with our hermetic sealing technology.

RHSeals epoxy sealed connectors offer better design flexibility than ceramic-to-metal and glass-to-metal seals along with a lower cost and better performance. Epoxy seals offer outgassing and leak rates comparable to ceramic and suitable for high and low volume applications. Epoxy connectors are used in a wide range of industries, including semiconductor manufacturing, automotive, aerospace, energy, and medical.

Epoxy sealed connectors are also ideal for custom seal designs thanks to greater flexibility and epoxy’s moldability.

Epoxy seals are replacing glass seals in many applications, including fuel connectors, leak detection systems, and nuclear glove boxes thanks to their high chemical resistance, compressive strength, and ability to withstand temperature cycling and pressure.

RHSeals Hermetic Connectors

Hermetically sealed connectors are gas- and air-resistant and suitable for applications in even extreme or harsh conditions, including high altitude, extreme pressure, and extreme weather. Hermetic connectors are frequently used in military applications like submarines and unmanned vehicles as well as industrial and commercial uses.

Hermetic connectors can thrive under even the harshest conditions and may be used with sensitive sensor and photographic equipment mounted to unmanned aerial vehicles that are exposed to extreme atmospheric pressure, rapidly changing temperatures, high altitude, and other severe weather.

A hermetically sealed connector is impervious to most gases and liquids, including alkalis, oils, acids, gasoline, hydraulic fluid, and jet fluid. They can also withstand shock loads up to 100 Gs without loss of hermeticity and withstand extreme cold or heat without a loss of performance.

Custom Hermetic Connectors

While we carry a range of stock connectors, many of our hermetic connectors are custom and engineered to meet very special requirements. This includes submarine-safe connectors for feedthroughs, aircraft engine connectors, and connectors that can withstand the intense temperature and pressure conditions for a missile.

Our catalog contains a range of standard hermetic connectors. If you do not find the right connector for your application, our engineering team can help.

If you have a custom need, contact RHSeals for help engineering the hermetically sealed connector that will match your project specifications. We can provide custom hermetic connectors to match an existing or specialty requirement as an alternative to a conventional connector.

Why RHSeals Hermetic Connectors?

Because the connectors we seal are frequently used in military-grade equipment, laboratories, and marine equipment, we always place the highest priority on quality with every connector we engineer and ship. Every RHSeals hermetic connector goes through rigorous testing after manufacture to ensure industry specifications are met. Before our connectors are sent out, they go through rigorous testing that includes dimensional inspection, helium leakage, electrical hipot, connector mateability, continuity, and visual workmanship.

We treat every order, even prototypes and low volume orders, with the utmost importance and strive to ship orders on time. Even custom made seals are guaranteed to be shipped by our promise date which can be as short as 2 weeks for custom connectors. With RHSeals, you can count on full support from the initial design stage through the life of your project with an experienced engineering team committed to providing the right hermetic connector for your application. Contact RHSeals today for assistance with a custom hermetically sealed connector if our catalog does not have a connector best suited for your application.

Contact RHSeals to develop a drawing for the hermetic connectors you need for your application and receive a detailed quote.

VIEW SOME OF OUR

PRODUCTS

RHSeals can create a hermetic seal for almost any connector you can find.

100% of parts go through a rigorous leak, electrical, & visual inspection.

One stop shop complete wire harnesses, electrically tested with our computer controlled equipment.