Fiber Optic Feedthrough

Fiber optic technology allows data to be carried from one point to another in the form of light through a strand of plastic or glass that serves as the transmission medium. The communications technology allowing signals to be sent down hair-thin strands of plastic or glass fiber began in the 1970s and began replacing copper in the 1980s.

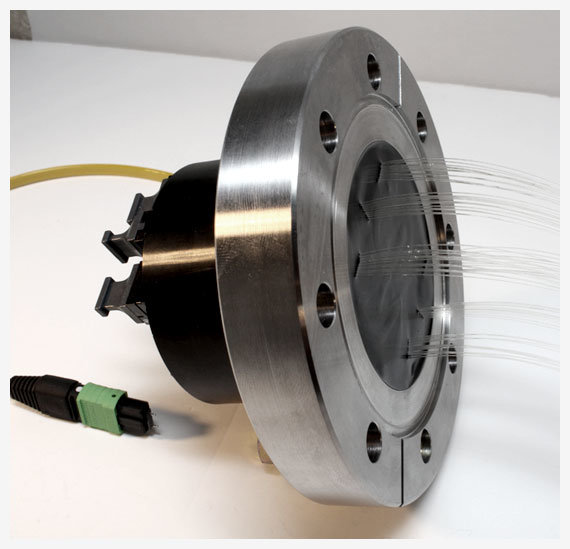

This technology comes with many advantages, especially compared to copper wire feedthroughs. A hermetically sealed fiber optic feedthrough maintains vacuum and pressure in both directions. Fiber optic feedthroughs allow data to be transferred over a longer distance than a traditional cable feedthrough, especially when cables are bundled. Our fiber optic vacuum feedthroughs are used in many applications, particularly aerospace, medical, research, and automotive.

RHSeals engineers and manufactures a wide range of fiber optic feedthroughs, including custom feedthroughs designed specifically for your project specifications. Our hermetically sealed feedthroughs offer a cost-effective alternative to copper feedthroughs with better performance and security. RHSeals optical fiber feedthroughs are manufactured for high vacuum applications with excellent leak rates and very low outgassing rates.

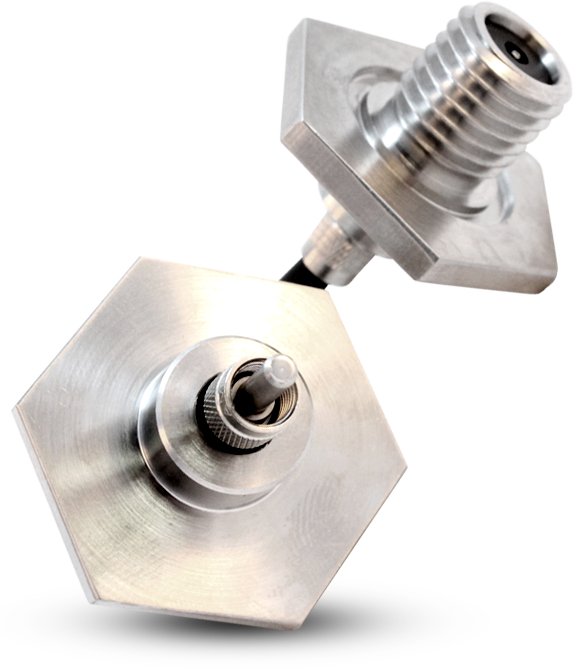

Our feedthroughs are designed for industry standard connectors like FSMA and FC/PC for high transmission and very low insertion loss at interconnects. If you need to pass optical fiber inside a vacuum system with a custom configuration, contact our engineering department for help building a robust solution made to your specifications.

Fiber Optic vs Copper Feedthroughs

A fiber optic feedthrough offers several advantages over a copper wire feedthrough due to its high bandwidth, low electrical conduction rates, and security. In fact, fiber optic cable is superior to copper in nearly every way.

Fiber optic feedthroughs can carry substantially more data than copper wire over a longer distance and with a lower weight. A single optical fiber can hold as much information as thousands of copper wires measuring several inches in diameter. With a much smaller size and weight, fiber optics offer maximum utilization of space, an important consideration in the aerospace industry and many other applications.

Its very wide bandwidth allows fiber optics to carry more information to minimize attenuation in a system. When a signal travels along a medium, it will naturally lose strength. With copper wire, attenuation increases as the frequency of the signal increases. With an optical fiber, attenuation remains nearly flat until very high frequencies. Over a distance of just two kilometers, copper wire would cause a significant degradation in quality while fiber optic cable would suffer almost no degradation.

Copper conductors also have issues with Electromagnetic Interference (EMI) affecting data signals unless they are correctly shielded. An exposed copper conductor can act as an antenna to receive or radiate energy. Fiber optics completely eliminate this susceptibility, making it immune to EMI and crosstalk. Because it’s incredibly difficult to tap into data from an optical fiber, fiber optics are considered one of the most secure transmission methods currently available. If optical fiber is tapped, it becomes immediately apparent as the system would fail because it would leak light.

Because optical fiber feedthroughs do not conduct electricity, they can be used in the automotive and aerospace industries without the concern of conducting electricity near fuel.

The cost of copper continues to rise while optical fiber becomes more affordable than ever; fiber optic feedthroughs represent a long-term economical solution for many applications.

Why Choose RHSeals Fiber Optic Feedthroughs?

Optical fiber feedthroughs combine the regulations of two forms of engineering: optical fibers and vacuum seals. This type of feedthrough must meet the standards of vacuum technology in terms of the materials used, helium leakage, outgassing, and maximum bake-out temperatures.

Other optical requirements must be met. This includes compatibility with common fiber connectors like FC/PC, FSMA and FC/APC, plus a low insertion loss and a high return loss.

RHSeals fiber optic feedthroughs match a broad range of applications from aerospace and automotive industries to spectroscopic applications. We offer fiber optic vacuum feedthroughs with single-mode and multimode fibers and customized fiber cables. If you have non-standard fibers, we can engineer a custom solution to fit the precise specifications of your application.

Contact RHSeals to develop a drawing for the Fiber Optic Feedthroughs you need for your application and receive a detailed quote.

VIEW SOME OF OUR

PRODUCTS

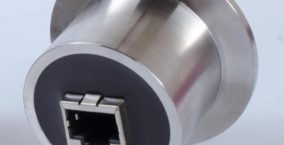

RHSeals can create a hermetic seal for almost any connector you can find.

100% of parts go through a rigorous leak, electrical, & visual inspection.

One stop shop complete wire harnesses, electrically tested with our computer controlled equipment.